Ingenious Fasteners and Machining Solutions for Intricate Layouts

Ingenious Fasteners and Machining Solutions for Intricate Layouts

Blog Article

Navigating the World of Fasteners and Machining: Strategies for Precision and Rate

In the detailed realm of fasteners and machining, the pursuit for accuracy and rate is a continuous obstacle that demands thorough focus to information and critical preparation. From recognizing the diverse array of fastener kinds to picking optimum products that can endure strenuous needs, each action in the process plays an essential function in attaining the wanted outcome.

Understanding Fastener Types

When choosing fasteners for a task, recognizing the numerous kinds readily available is crucial for making certain optimum efficiency and integrity. Bolts can be found in a vast array of kinds, each made for details applications and requirements. Screws are used with nuts to hold products together, while screws are versatile bolts that can be utilized with or without a nut, relying on the application. Nuts, on the other hand, are internally threaded bolts that mate with bolts or screws, supplying a safe and secure hold. Washing machines are vital for distributing the lots of the fastener and preventing damages to the material being attached. Furthermore, rivets are permanent bolts that are optimal for applications where disassembly is not required. Recognizing the distinctions between these bolt types is essential for picking the right one for the job, ensuring that the link is solid, sturdy, and reliable. By selecting the proper fastener type, you can optimize the efficiency and long life of your task - Fasteners and Machining.

Choosing the Right Products

Understanding the value of selecting the ideal materials is vital in guaranteeing the optimum performance and reliability of the selected fastener kinds discussed previously. When it pertains to bolts and machining applications, the material choice plays a crucial role in identifying the general strength, longevity, corrosion resistance, and compatibility with the intended atmosphere. Various products use differing buildings that can significantly impact the performance of the fasteners.

Common materials used for fasteners include steel, stainless steel, brass, titanium, and light weight aluminum, each having its one-of-a-kind strengths and weaknesses. Steel is renowned for its high stamina and toughness, making it appropriate for a vast range of applications. Stainless steel provides exceptional deterioration resistance, ideal for atmospheres susceptible to moisture and chemicals. Light weight aluminum is light-weight and corrosion-resistant, making it suitable for applications where weight reduction is essential. Brass is typically selected for its visual charm and superb conductivity. Titanium is known for its outstanding strength-to-weight ratio, making it perfect for high-performance applications. Selecting the right product includes considering variables such as stamina demands, environmental problems, and budget constraints to make certain the preferred efficiency and long life of the bolts.

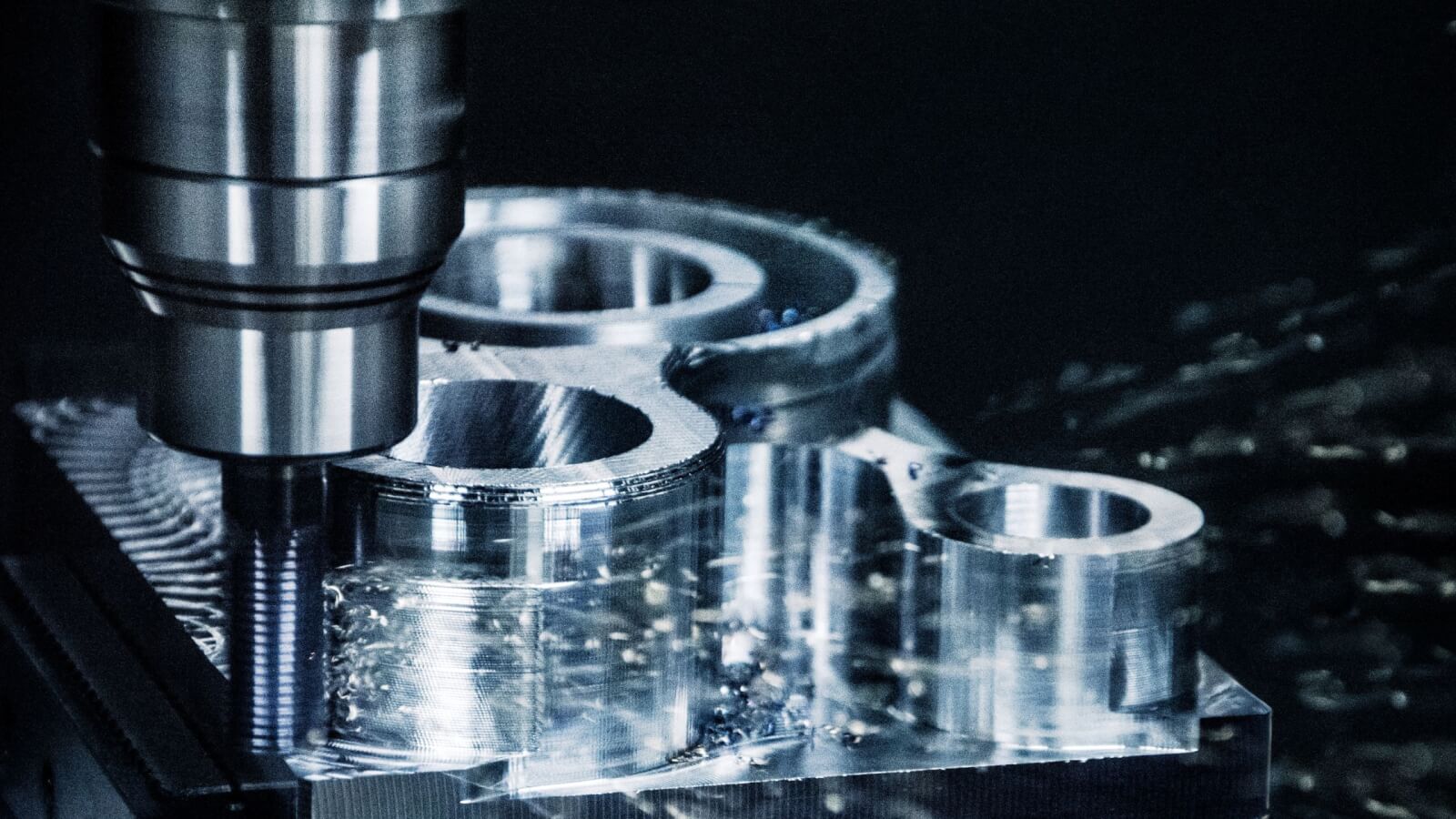

Precision Machining Techniques

Along with CNC machining, other accuracy strategies like grinding, transforming, milling, and exploration play important functions in bolt manufacturing. Grinding aids attain great surface area coatings and tight dimensional tolerances, while transforming is commonly made use of to develop round parts with precise diameters. Milling and drilling operations are crucial for shaping and developing openings in fasteners, imp source ensuring they satisfy exact specs and function correctly.

Enhancing Rate and Efficiency

To optimize bolt manufacturing procedures, it is important to streamline procedures and apply efficient techniques that complement accuracy machining methods. One crucial technique for improving speed and performance is the implementation of lean manufacturing principles. By decreasing waste and focusing on continuous improvement, lean practices help get rid of bottlenecks and enhance process. Furthermore, investing in automation innovations can dramatically boost manufacturing rate. Automated systems can take care of recurring jobs with accuracy and speed, allowing workers to focus on even more complex and value-added tasks. Taking On Just-In-Time (JIT) supply monitoring can additionally boost performance by ensuring that the appropriate products are readily available at the ideal time, decreasing excess supply and reducing lead times. Additionally, promoting a culture of cooperation and communication amongst staff member can boost total effectiveness by promoting openness, analytical, and development. By combining these strategies, suppliers read the full info here can accomplish a balance in between speed and accuracy, ultimately boosting their competitive side in the fastener sector.

High Quality Control Measures

Executing strenuous top quality control steps is essential in guaranteeing the reliability and consistency of fastener items in the production process. Fasteners and Machining. Quality control steps incorporate numerous phases, starting from the option of raw materials to the final examination of the completed fasteners. This entails evaluating factors such as product sturdiness, structure, and strength to ensure that the bolts satisfy sector criteria.

Routine go to my blog calibration of devices and equipment is essential to keep consistency in production and ensure that bolts satisfy the needed tolerances. Implementing rigorous protocols for recognizing and resolving non-conformities or defects is crucial in avoiding substandard products from getting in the marketplace. By establishing a detailed quality control structure, makers can maintain the credibility of their brand name and provide fasteners that fulfill the highest requirements of performance and longevity.

Final Thought

In the intricate realm of bolts and machining, the pursuit for accuracy and speed is a perpetual difficulty that demands precise interest to detail and calculated preparation. When it comes to bolts and machining applications, the material choice plays a critical duty in determining the overall stamina, resilience, rust resistance, and compatibility with the intended environment. Precision machining involves numerous innovative approaches that make sure the tight tolerances and specifications needed for bolts.In enhancement to CNC machining, other precision strategies like grinding, transforming, milling, and boring play important roles in bolt manufacturing.To enhance fastener production procedures, it is crucial to enhance operations and implement efficient approaches that match precision machining strategies.

Report this page